10000L commercial beer fermenters and bright beer tanks for industry brewery

In the ever-evolving world of craft brewing, quality and efficiency are paramount to success. To meet the growing demands of the industry, we are proud to introduce our cutting-edge 10,000L commercial beer fermenters and bright beer tanks. These state-of-the-art vessels are designed to elevate your brewery operations to new heights, ensuring exceptional beer quality and production efficiency.

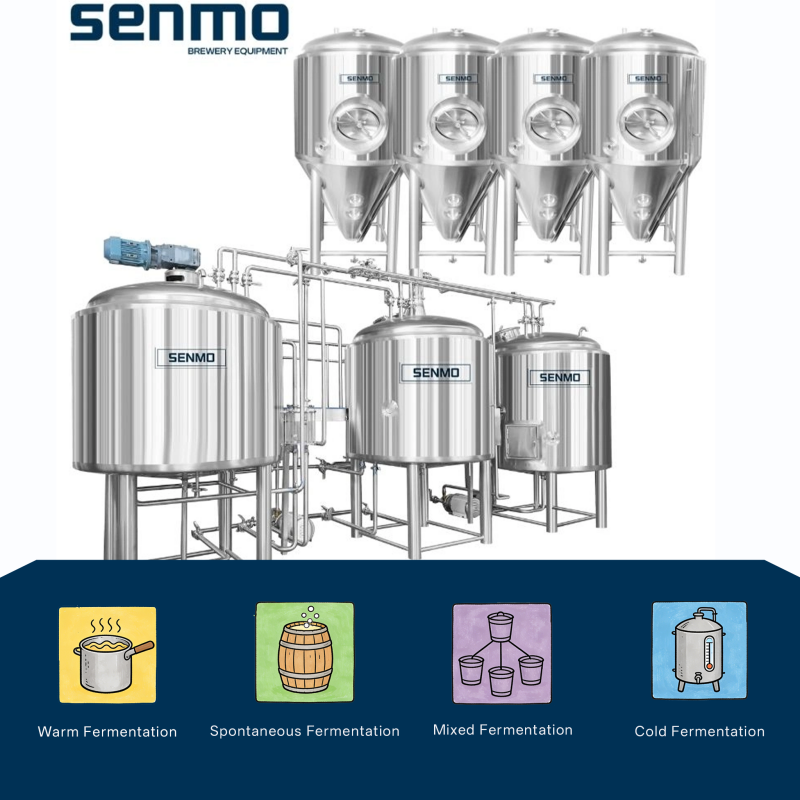

This is our 10000L commercial beer fermenters and bright beer tanks for sale. The whole fermentation system for sale is customized deigned and produced,it includes the beer tanks,pipelins,fittings&valves and etc.

Beer Tanks: The heart of any brewery, our 10,000L commercial beer fermenters and bright beer tanks are crafted with precision from high-quality stainless steel. These tanks ensure the optimal conditions for fermentation and beer storage. With a 10,000L capacity, they are perfect for high-volume production and scalability.

Pipelines: We provide a complete set of pipelines tailored to your brewery's layout and requirements. From wort transfer to cooling and cleaning, our pipelines are designed for efficiency and ease of use.

Fittings & Valves: The devil is in the details, and our fittings and valves are chosen for their quality and reliability. They play a crucial role in maintaining the integrity of your brewing process and ensuring the longevity of your equipment.

We understand that every brewery has its unique operational needs. That's why we offer extensive customization options:

Size and Capacity: Whether you need a smaller or larger system, we can adapt the design to meet your requirements. Our 10,000L tanks are just one option in our portfolio.

Layout and Configuration: Your brewery's layout matters. We can tailor the system to fit seamlessly into your existing setup, maximizing space and workflow efficiency.

Control Systems: Choose the level of automation that suits your operation. We can provide user-friendly control panels and automation features to streamline your brewing process.

Material and Finish: Select the material and finish that matches your brand's aesthetic and hygiene standards. Stainless steel, polished, or matte, we've got you covered.

Investing in a customized 10,000L commercial beer fermentation system is an investment in your brewery's success. Our tailor-made equipment ensures top-tier beer quality, production efficiency, and operational convenience. From beer tanks to fittings and valves, every component is crafted with precision and quality in mind.

The 10000L beer fermentation tank and bright beer tank plates and accessories are made of international standard SUS304 stainless steel; Laser cutting and argon shielded welding, internal centralized pickling and passivation, accuracy ≤ 0.4 μ m; Polyurethane foam insulation; Pipe fittings support DIN, ISO, SMS and other customized standards;Dimple cooling jacket test pressure is 0.4MPa; The working pressure of the beer fermentation tank and bright beer tank is 0.15 MPa, and the test pressure is 0.4 MPa;It has top stainless steel dished head, lower 60 ° cone bottom; Manhole can be on top or side of the beer fermenter.High precision temperature sensor, automatic temperature control, real-time feedback of temperature curve, supporting remote operation;

At the heart of a brewery's operations, precision, quality, and efficiency are of utmost importance. Our 10,000L Beer Fermentation Tank and Bright Beer Tank are designed and manufactured to meet and exceed international standards. Here's a detailed breakdown of their features:

1. Material and Welding

Material: The plates and accessories of these tanks are constructed from high-quality international standard SUS304 stainless steel. This ensures excellent corrosion resistance and longevity.

Welding: Laser cutting and argon-shielded welding techniques are employed to maintain the integrity and hygiene of the tanks. This process guarantees exceptional precision, with an accuracy level of ≤ 0.4 μm.

2. Insulation

Polyurethane Foam: The tanks are insulated with polyurethane foam. This insulation not only maintains the desired temperature but also ensures energy efficiency during the brewing process.

3. Pipe Fittings

Standards: The tanks support a range of standards for pipe fittings, including DIN, ISO, SMS, and customization to meet your specific requirements. This versatility allows seamless integration with your existing brewery setup.

4. Cooling System

Dimple Cooling Jacket: The dimple cooling jacket is designed to withstand a test pressure of 0.4MPa. It efficiently regulates and controls the temperature during fermentation and storage, contributing to the consistency and quality of your brews.

5. Pressure Rating

Working Pressure: The working pressure of both the beer fermentation tank and bright beer tank is rated at 0.15 MPa. This ensures safety and reliability during the brewing process.

Test Pressure: To guarantee the tanks' structural integrity, they are tested at a pressure of 0.4 MPa, well above the working pressure, to ensure they can withstand the rigors of brewery operations.

6. Design and Manhole

Design: The tanks feature a top stainless steel dished head and a lower 60° cone bottom. This design optimizes the fermentation and storage process, facilitating the natural separation of solids and liquids.

Manhole: The manhole can be positioned on either the top or side of the beer fermenter, offering flexibility in accessing and maintaining the tanks.

7. Temperature Control

Temperature Sensor: High-precision temperature sensors are integrated into the tanks, enabling automatic temperature control. This real-time feedback of temperature curves ensures that your brews maintain the desired conditions throughout the fermentation process.

Remote Operation: The tanks support remote operation, allowing you to monitor and control the brewing process from a distance, offering convenience and efficiency in managing your brewery.

Our 10,000L Beer Fermentation Tank and Bright Beer Tank embody quality, precision, and innovation. These tanks are designed to meet the exacting standards of the brewing industry, providing brewers with the tools they need to create exceptional, consistent, and high-quality beer. Whether you're an established brewery or looking to scale up your operations, these tanks are the ideal choice for elevating your brewing process.

Our Service

If you have plan to expand your brewery by adding more fermenters and bright beeer tanks,you can contact with us and ask for the proposal of the whole fermentation system for sale. Below is the services which we provide fo you:

Sales consulting. SENMO provide fast, professional and detailed beer brewery equipment configuration list according to customer requirements.

Brewery technical design. According to the concept of customization, put forward design suggestions, integrate customer requirements, issue beer brewing process flow diagrams,micro brewery floor plans,machinery, electrical and other drawings, draw 3D drawing, and provide one-to-one tracking services.

Brewery equipment processing and manufacturing. Strictly implement the requirements of beer equipment design drawings, follow the IOS9001 quality management system, strictly control the quality of all links, and provide tanks test records of plates, welding, polishing, pressure, etc. for filing.

Brewery plant delivery and installation. The professional brewery project construction team conducts on-site installation, commissioning and training to ensure accurate delivery for use and continuous tracking maintenance.

Conclusion

Our 10,000L commercial beer fermenters and bright beer tanks represent a significant leap forward in brewery equipment technology. They enable brewers to craft high-quality beer with unprecedented efficiency, catering to the ever-growing demands of the industry.

Investing in these state-of-the-art vessels is not just an investment in your brewery; it's an investment in the future of your brand. Elevate your brewing game, meet market demand, and stay ahead of the competition with our cutting-edge brewing solutions. Discover the difference that our 10,000L commercial beer fermenters and bright beer tanks can make in your brewery operations today. Cheers to great beer and even greater success!

FAQ

1. What are commercial beer fermenters and bright beer tanks, and how do they work?

Commercial beer fermenters are large vessels used for the fermentation of beer, where yeast converts sugars into alcohol and carbon dioxide. Bright beer tanks are used for beer maturation and storage before packaging. These tanks are equipped with temperature control, pressure regulation, and other features to ensure the quality and consistency of the beer.

2. What are the primary materials used in these tanks?

Our 10,000L commercial beer fermenters and bright beer tanks are made of international standard SUS304 stainless steel, known for its excellent corrosion resistance and hygiene properties.

3. How is the precision of the tanks maintained?

The tanks are manufactured using laser cutting and argon-shielded welding techniques, ensuring precision with an accuracy level of ≤ 0.4 μm.

4. Can the tanks be customized to fit my brewery's needs?

Yes, we offer customization options for size, layout, control systems, and more. We can adapt the tanks to seamlessly integrate into your existing brewery setup.

5. What is the insulation material used in the tanks, and why is it important?

Polyurethane foam insulation is used to regulate and maintain temperature within the tanks. It is essential for energy efficiency during the brewing process.

6. What types of pipe fittings are supported by these tanks?

The tanks support various pipe fitting standards, including DIN, ISO, SMS, and can be customized to meet your specific requirements.

7. Can I control the tanks remotely?

Yes, the tanks support remote operation. You can monitor and control the brewing process from a distance, offering convenience and efficiency in managing your brewery.

8. What are the pressure ratings of these tanks?

The working pressure of both the beer fermentation tank and bright beer tank is rated at 0.15 MPa, ensuring safety and reliability during brewing operations. The tanks are tested at a pressure of 0.4 MPa to guarantee their structural integrity.

9. Where can the manhole be positioned on the tanks?

The manhole can be positioned on either the top or side of the beer fermenter, offering flexibility in accessing and maintaining the tanks.

10. Are these tanks suitable for both large and small breweries?

Yes, our 10,000L tanks are versatile and can be used in both large and small breweries. They are ideal for high-volume production, making them a valuable addition to your brewery, whether you are scaling up or are an established brewery.

11. How can I purchase these tanks?

To inquire about purchasing these 10,000L commercial beer fermenters and bright beer tanks for your industry brewery, please contact our sales team for pricing, customization options, and ordering information. We are here to assist you in finding the perfect solution for your brewing needs.

If you have any additional questions or need further information, please do not hesitate to contact us.