What is 10BBL 4-vessel industrial brewing equipment ?

10BBL 4-vessel industrial brewing equipment refers to a brewing system designed for large-scale commercial breweries. It has a brewing capacity of 10 barrels, which is equivalent to approximately 310 gallons or 1,163 liters. The "4-vessel" designation indicates that the brewing system consists of four separate vessels, each serving a specific function in the brewing process. Here are the key components and functions of the 10BBL 4-vessel industrial brewing equipment:

1. Mash/Lauter Tun: The mash/lauter tun is the first vessel in the brewing process. It is used for mashing, where crushed grains are mixed with hot water to convert starches into fermentable sugars. Lautering follows, which involves separating the liquid wort from the solid grain bed.

2. Brew Kettle: The brew kettle is where the wort is boiled with hops and other ingredients to extract flavors and bitterness. Boiling also helps sterilize the wort and concentrate flavors.

3. Whirlpool: The whirlpool vessel is used to separate hot trub and hop residues from the boiled wort. It creates a gentle swirling motion that collects the solids in the center of the vessel for easy removal.

4. Hot Liquor Tank (HLT): The HLT stores and heats the water needed for various brewing processes, such as mashing and sparging.

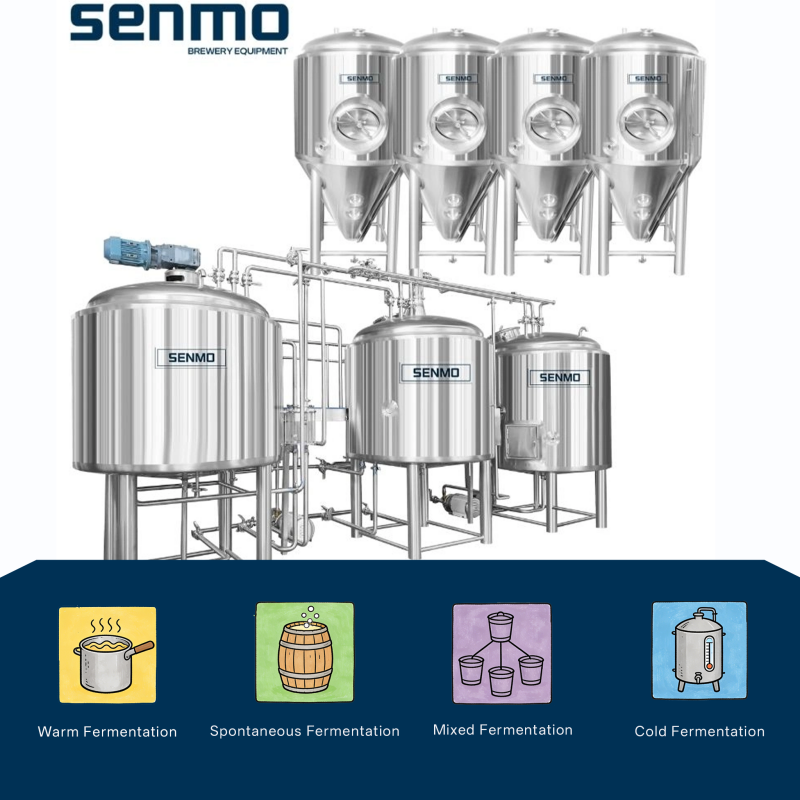

5. Fermentation Tanks: After the brewing process is complete, the wort is transferred to fermentation tanks. Yeast is added, and fermentation occurs, converting sugars into alcohol and carbon dioxide, turning the wort into beer.

6. Glycol Cooling System: The equipment is equipped with a glycol cooling system, including cooling jackets on the fermentation tanks. This system helps control fermentation temperatures for optimal beer quality.

7. Control System: The industrial brewing equipment is integrated with a sophisticated control system, allowing brewers to manage and monitor temperatures, flow rates, and other brewing parameters with precision and automation.

8. Cleaning-In-Place (CIP) System: The CIP system facilitates the automated cleaning and sanitation of the brewing equipment between batches, ensuring high levels of hygiene and efficiency.

9. Stainless Steel Construction: The entire brewing equipment is constructed using high-quality stainless steel, ensuring durability, ease of cleaning, and resistance to corrosion.

10BBL 4-vessel industrial brewing equipment is designed for large-scale breweries that produce significant volumes of beer. It offers advanced automation, precise control over brewing parameters, and the capacity to brew a wide range of beer styles to meet the demands of the commercial market. This brewing system empowers breweries to maintain consistency, efficiency, and quality while meeting the production requirements of a thriving brewing business.

This is our 10bbl 4-vessel industrial brewing equipment for sale.Besides of the 4-vessel brewing equipment,it also has the hot water tank and cold water tank.The whole brewing equipment system includes the following items.

10bbl steam heated mash tun

10bbl beer lauter tun

10bbl steam heated wort kettle

10bbl beer whirlpool tun

20bbl steam heated hot water tank

20bbl cold water tank

12M2 plate heat exchanger

Wort pumps and water pumps

Stainless stell pipelins

Wort grant tank

Operation platform

Brewhouse control cabinet

If you want build a microbrewery plant with 10bbl per batch brewing equipment,then this brewing system for sale is a good choice.The whole beer cooking system is automatically control,with PLC control panel,you can edit the brewing recipes and save the programs,next time when you brew same beer,you can just use it without inputing the recipe again.

We use enlarged operation platform on the cooking system,it makes the brewers operation more convenient,you can put the grain bags on the platform before mashing,and you can put other brewing device on it such as the wort inspection device.

With this 10bbl industrial brewing equipment,you can have 10bbl beer fermentation tanks,20bbl fermenters,30bbl beer fermenters,40bbl beer fermenters and 50bbl fermenters for in your brewery. The maximum wort output is 50bbl per day(24 hours),so,you can do mutiple wort brewing capacity using this equipment.

As a beer equipment manufacturer who provide turnkey beer brewing solution,SENMO alwasy provide you with the most professional brewery plant equipment as per your requirements.

The control panel using PLC system can show the whole 10bbl industrial brewing equipment flowchart.You can operate the valves by pressing the icons on the touch screen,you can observe the temperature of each vessels,the status of the valves and pumps through the control panel.

Before the brewing equipment production,our engineer will do the layout design as per your brewery floor plan,it can make sure the brewery equipment can fit into your building,and you can make the drainage ditch,electric power source,water source in advance. Beside of the floor plan drawing,we also provide the brewing technical drawing,tanks data drawings for you to confirm before production.

FAQ

Q1: What is the capacity of the 10BBL 4-vessel industrial brewing equipment?

A: The 10BBL 4-vessel industrial brewing equipment has a brewing capacity of 10 barrels, which is approximately 310 gallons or 1,163 liters.

Q2: What are the four vessels included in the brewing equipment?

A: The four vessels are the Mash/Lauter Tun, Brew Kettle, Whirlpool, and Hot Liquor Tank (HLT), each serving a specific function in the brewing process.

Q3: Is the brewing equipment made of stainless steel?

A: Yes, the entire brewing equipment is constructed using high-quality stainless steel, ensuring durability, ease of cleaning, and resistance to corrosion.

Q4: What is the function of the Mash/Lauter Tun?

A: The Mash/Lauter Tun is used for mashing, where crushed grains are mixed with hot water to convert starches into fermentable sugars. It also serves to separate the liquid wort from the solid grain bed during lautering.

Q5: What happens in the Brew Kettle?

A: The Brew Kettle is where the wort is boiled with hops and other ingredients to extract flavors and bitterness. Boiling also helps sterilize the wort and concentrate flavors.

Q6: What is the purpose of the Whirlpool vessel?

A: The Whirlpool vessel is used to separate hot trub and hop residues from the boiled wort. It creates a gentle swirling motion that collects the solids in the center of the vessel for easy removal.

Q7: How is temperature control maintained during fermentation?

A: The brewing equipment is equipped with a glycol cooling system, including cooling jackets on the fermentation tanks. This system helps control fermentation temperatures for optimal beer quality.

Q8: Does the equipment offer automation and precise control over brewing parameters?

A: Yes, the industrial brewing equipment is integrated with a sophisticated control system, allowing brewers to manage and monitor temperatures, flow rates, and other brewing parameters with precision and automation.

Q9: How is the brewing equipment cleaned between batches?

A: The brewing equipment is equipped with a Cleaning-In-Place (CIP) system, which facilitates the automated cleaning and sanitation of the brewing equipment between batches, ensuring high levels of hygiene and efficiency.

Q10: Is the 10BBL 4-vessel industrial brewing equipment suitable for large-scale breweries?

A: Yes, the equipment is specifically designed for large-scale commercial breweries that produce significant volumes of beer, offering efficiency, consistency, and quality for the demands of the commercial market.

Q11: Can the brewing equipment handle a wide range of beer styles?

A: Absolutely! The 10BBL 4-vessel industrial brewing equipment provides versatility, allowing breweries to brew a wide variety of beer styles to cater to diverse consumer preferences.

Q12: How can I obtain more information or request a quote for the 10BBL 4-vessel industrial brewing equipment?

A: For more information or to request a quote for the 10BBL 4-vessel industrial brewing equipment, please contact our sales team. We are committed to providing all the necessary details and support to meet your brewing needs and aspirations.

If you have plan to open your own microbrewery,and you want to know more about the 10bbl industrial brewery equipment for sale,please send us inquiry,we have sales engineer who can give you the professional solution on it.Cheers!