15 bbl 1500L beer brewing equipment is widely used in the beer brewing industry. It is suitable for small and medium-sized breweries, bars, restaurants, and hotels. This equipment is designed to produce high-quality beer with consistent taste and aroma. In this article, we will discuss the specifications, prices, materials, application scenarios, manufacturing, transportation, and maintenance of 15 bbl 1500L beer brewing equipment.

Specifications:

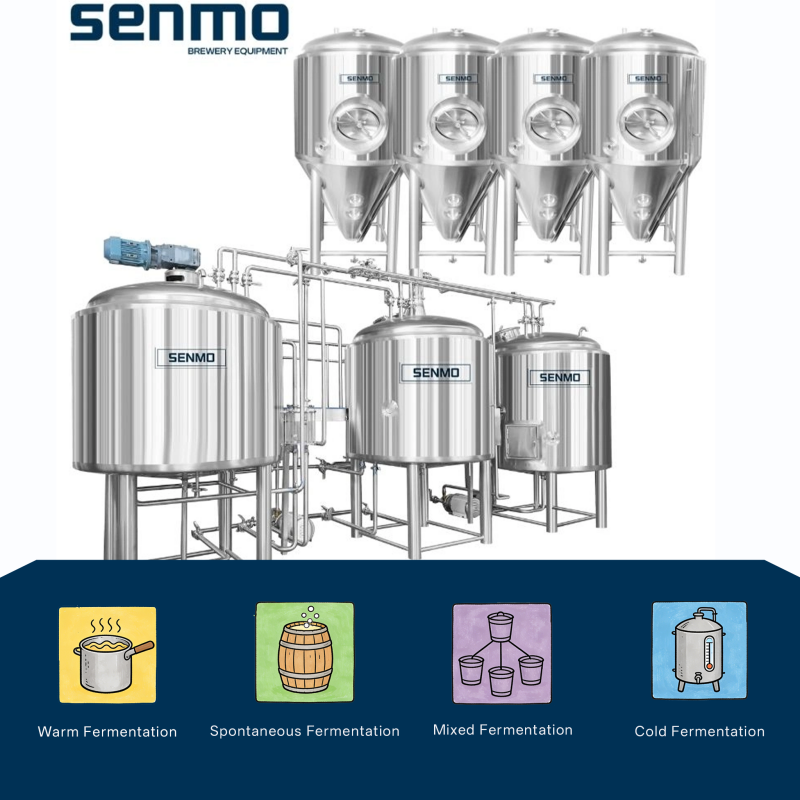

The 15 bbl 1500L beer brewing equipment consists of a mash tun, lauter tun, kettle, whirlpool, hot liquor tank, and a control panel. The mash tun has a capacity of 1500L, and the lauter tun, kettle, and whirlpool have a capacity of 15 bbl. The hot liquor tank has a capacity of 3000L. The equipment is made of high-quality stainless steel, which ensures durability and longevity.

Prices:

The price of 15 bbl 1500L beer brewing equipment varies depending on the manufacturer, materials, and specifications. The average price of this equipment is around $53,000 to $106,000. However, the price may go up or down depending on the features and accessories.

Materials:

The 15 bbl 1500L beer brewing equipment is made of high-quality stainless steel. The stainless steel used in this equipment is food-grade, which ensures that the beer produced is safe for consumption. The stainless steel also provides durability and longevity to the equipment.

Application Scenarios:

The 15 bbl 1500L beer brewing equipment is suitable for small and medium-sized breweries, bars, restaurants, and hotels. It is designed to produce high-quality beer with consistent taste and aroma. This equipment can produce a variety of beer styles, including lagers, ales, stouts, and porters.

Manufacturing:

The manufacturing process of 15 bbl 1500L beer brewing equipment involves several steps. First, the stainless steel is cut into the required shapes and sizes. Then, the parts are welded together to form the equipment. After that, the equipment is polished and cleaned to ensure that it is free from any impurities. Finally, the equipment is tested to ensure that it meets the required standards.

Transportation:

The 15 bbl 1500L beer brewing equipment is usually transported by sea or air. The equipment is packed in wooden crates or pallets to ensure that it is safe during transportation. It is important to ensure that the equipment is properly secured during transportation to prevent any damage.

Maintenance:

The 15 bbl 1500L beer brewing equipment requires regular maintenance to ensure that it functions properly. It is important to clean the equipment after each use to prevent any bacteria growth. The equipment should also be inspected regularly to ensure that it is free from any defects or damages. It is recommended to hire a professional technician to perform maintenance on the equipment.

In conclusion, the 15 bbl 1500L beer brewing equipment is a high-quality and durable equipment that is suitable for small and medium-sized breweries, bars, restaurants, and hotels. It is made of high-quality stainless steel, which ensures that the beer produced is safe for consumption. The equipment is easy to transport and maintain, and it is designed to produce high-quality beer with consistent taste and aroma.

FAQ

1. What is a 15 bbl (1500L) beer brewing system?

A 15 bbl (barrel) beer brewing system has a total capacity of 15 barrels or approximately 1500 liters (396 gallons). It's a brewery setup used for producing larger batches of beer and is suitable for mid-sized craft breweries.

2. What components are typically included in a 15 bbl brewing system?

A 15 bbl brewing system typically includes vessels such as a mash tun, lauter tun, boil kettle, hot liquor tank (HLT), fermentation tanks, a cooling system, control panel, pumps, and various additional equipment for specific brewing needs.

3. How many batches can I brew with a 15 bbl system?

The number of batches you can brew with a 15 bbl system depends on factors like production time, fermentation time, and packaging volume. On average, a brewery may produce several batches per week.

4. Is this system suitable for a startup brewery?

A 15 bbl brewing system is typically considered more suitable for established or mid-sized craft breweries due to its larger production capacity and associated costs.

5. What beer styles can I brew with this system?

A 15 bbl system is versatile and allows you to brew a wide range of beer styles. Brewers can adjust recipes and techniques to create various beer flavors and styles.

6. How do I control the brewing process with this system?

Many 15 bbl systems come with a control panel that allows you to monitor and adjust factors like temperature, timing, and pump operations, ensuring precise control over the brewing process.

7. What's the brewing process with a 15 bbl system?

The brewing process involves mashing, lautering, boiling, cooling, fermentation, and packaging. Each step is carefully managed to create high-quality beer.

8. How long does it take to brew a batch of beer with this system?

The time required to brew a batch of beer varies depending on the beer style and specific techniques used. On average, it can take several hours for brewing, followed by fermentation and conditioning periods that may last weeks to months.

9. Can I expand my production with this system?

Yes, a 15 bbl brewing system can be expanded by adding more fermentation tanks or increasing batch frequency to meet growing demand.

10. What maintenance is required for the equipment?

Routine cleaning and sanitation are essential for maintaining the equipment's hygiene. Regular inspection, maintenance, and cleaning of tanks, pipes, and pumps are necessary for optimal operation.

11. Is training available for using the system?

We offer training and support to help brewers operate and maintain their 15 bbl brewing systems effectively.

12. What utilities are required to operate a 15 bbl system?

A 15 bbl system typically requires access to water, electricity, natural gas or propane for heating, and a wastewater disposal system. The specific requirements may vary based on the equipment and brewery setup.

These FAQs provide an overview of a 15 bbl beer brewing system and its use in a brewery. However, detailed questions and considerations may vary depending on your brewery's unique requirements and brewing practices.