Brewing beer is a complex process that requires specialized equipment. For small-scale breweries, a 7 BBL brewing system is an ideal choice. This size is perfect for producing enough beer to meet the demand of a small customer base while keeping costs manageable. In this article, we will explore the 7 BBL brewing equipment and its main accessories, output, usage scenarios, how to purchase a 3-vessel electric brewing system, and the cost.

Main Accessories of 7 BBL Brewing Equipment

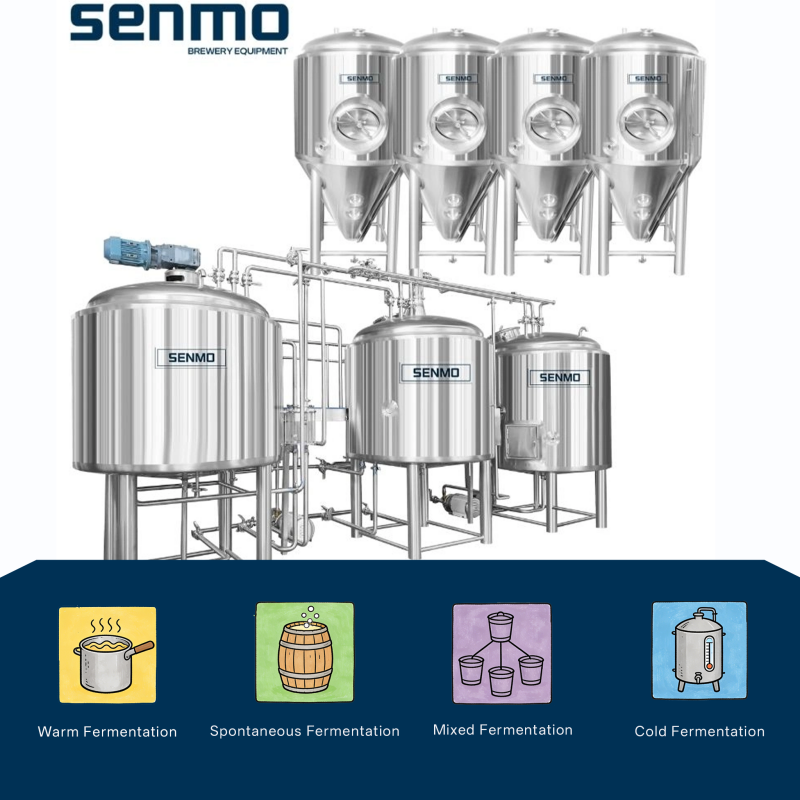

The main accessories of a 7 BBL brewing system include a mash tun, a brew kettle, and a fermenter. The mash tun is used to mix the grains with hot water to create a mash. The brew kettle is used to boil the wort, which is the liquid extracted from the mash. The fermenter is used to ferment the wort into beer. Other accessories include a heat exchanger, pumps, and a control panel.

Mash Tun

The mash tun is a vessel where the process of mashing takes place. It is used to mix crushed grains (such as malted barley) with hot water to create a mash. During this process, enzymes in the malt convert starches into sugars, forming the sweet wort that will later be boiled.

Brew Kettle

The brew kettle is where the wort is boiled and hops are added. This vessel is responsible for sterilizing the wort, extracting flavors and bitterness from the hops, and evaporating unwanted compounds. After boiling, the wort is rapidly cooled and transferred to a fermenter.

Fermenter

The fermenter is a vessel where the wort is fermented by yeast. During fermentation, yeast consumes the sugars in the wort and produces alcohol and carbon dioxide. This is where the wort transforms into beer. Fermenters can be made of stainless steel or other materials and are equipped with airlocks and temperature control systems.

Heat Exchanger

A heat exchanger is used to rapidly cool the boiled wort before it enters the fermenter. It typically consists of a series of tubes or plates through which cold water or glycol circulates. This process quickly lowers the temperature of the wort to a level suitable for fermentation.

Pumps

Pumps are essential for transferring liquids throughout the brewing process. They are used to move hot water, wort, and sometimes even cleaning solutions from one vessel to another. Pumps help maintain a consistent flow and ensure efficient brewing operations.

Control Panel

The control panel is the brain of the brewing system. It allows the brewer to monitor and control various aspects of the brewing process, including temperature, timing, and pump operation. Advanced control panels may include touchscreen interfaces and automation features.

Additional accessories and components can be integrated into a 7 BBL brewing system to enhance efficiency and automation. These may include grain mills, hoses, valves, and instrumentation for measuring parameters such as temperature and pressure. The specific configuration of a brewing system can vary depending on the brewery's needs and budget.

Output of 7 BBL Brewing Equipment

A 7 BBL brewing system can produce approximately 210 gallons of beer per batch. This output is perfect for small-scale breweries that want to provide a variety of beers to their customers without having to produce large quantities. It provides a balance between batch size and production capacity, allowing brewers to experiment with different recipes and maintain a manageable level of production. The versatility of a 7 BBL system makes it a popular choice for craft breweries and microbreweries looking to cater to local or niche markets while ensuring the quality and freshness of their beers.

Usage Scenarios of 7 BBL Brewing Equipment

The usage scenarios of a 7 BBL (barrel) brewing equipment are indeed well-suited for various settings, particularly those aiming for small-scale production with a focus on variety and quality. Here are some detailed usage scenarios:

Brewpubs

7 BBL brewing systems are a popular choice for brewpubs that want to brew their beer on-site and offer a rotating selection of craft brews to their customers. The system's manageable batch size allows brewpubs to maintain a consistent supply of fresh and unique beers tailored to their customer base.

Taprooms

Breweries with attached taprooms often use 7 BBL equipment to brew small-batch and experimental beers for their taproom patrons. This enables them to continuously offer new and exciting beer options, fostering customer loyalty and creating a distinct brand identity.

Small Craft Breweries

Smaller craft breweries that prioritize quality and diversity in their beer offerings find 7 BBL systems to be a practical choice. These breweries can experiment with recipes, seasonal releases, and limited editions while maintaining production efficiency.

Niche and Specialized Breweries

Niche or specialized breweries, such as those focusing on sour beers, barrel aging, or specific beer styles, can benefit from the flexibility of a 7 BBL system. It allows them to craft unique and highly sought-after brews for a dedicated customer base.

Local Distribution

Breweries with a focus on local distribution can use 7 BBL equipment to supply nearby bars, restaurants, and retailers with a steady stream of fresh beer. This ensures a consistent presence in the local market and supports community engagement.

Collaborations

Smaller breweries often engage in collaborations with other breweries or businesses. The 7 BBL system's batch size is suitable for collaborative projects where multiple parties come together to create a limited-edition beer.

Seasonal and Limited Releases

Breweries can use 7 BBL systems to produce seasonal and limited-release beers, aligning with holidays, festivals, or special occasions. These beers generate excitement among customers and drive sales.

Educational and Training Facilities

Brewing schools and educational institutions often utilize 7 BBL brewing equipment for hands-on training and brewing education programs. It provides students with practical experience on a scale relevant to many craft breweries.

In summary, a 7 BBL brewing system is versatile and adaptable, making it an ideal choice for small-scale breweries, brewpubs, taprooms, and other settings where the emphasis is on producing a diverse range of high-quality and unique beers. It allows brewers to experiment, cater to local tastes, and engage with their customers on a personal level, contributing to the success of the craft beer industry.

How to Purchase a 3-Vessel Electric Brewing System

7 BBL brewing system is 3-vessel electric brewing system. When purchasing a 3-vessel electric brewing system, it is important to consider the quality of the equipment, the reputation of the manufacturer, and the level of customer support provided. It is also important to consider the features of the brewing system, such as the control panel, the heat exchanger, and the pumps. If you want to purchase 7 BBL Brewing Equipment, it is recommended to purchase from regular Brewing Equipment manufacturers. In particular, some small and medium-sized manufacturers all provide equipment customization services, with advantages in price and service, such as senmo machinery.

Cost of 7 BBL Brewing Equipment

The cost of a 7 BBL brewing system can vary depending on the manufacturer and the features of the equipment. A basic 3-vessel electric brewing system can cost between $20,000 and $30,000. However, more advanced systems with additional features can cost up to $50,000 or more.

Conclusion

A 7 BBL brewing system is an ideal choice for small-scale breweries that want to produce a variety of beers without having to invest in large-scale equipment. The main accessories of a 7 BBL brewing system include a mash tun, a brew kettle, and a fermenter. The output of a 7 BBL brewing system is approximately 210 gallons of beer per batch. When purchasing a 3-vessel electric brewing system, it is important to consider the quality of the equipment, the reputation of the manufacturer, and the level of customer support provided. The cost of a 7 BBL brewing system can vary depending on the manufacturer and the features of the equipment.

FAQ

What is 7 BBL brewing equipment, and what does it include?

7 BBL brewing equipment refers to a brewing system with a 7-barrel capacity. It typically includes essential components such as a mash tun, lauter tun, kettle, whirlpool, fermentation tanks, and associated pumps, heat exchangers, and control systems for brewing beer.

Is this equipment suitable for a small-scale brewery?

Yes, 7 BBL brewing equipment is well-suited for small-scale breweries. It allows for a reasonable batch size, making it a popular choice for craft breweries and microbreweries.

What types of beer can I brew with this equipment?

You can brew a wide range of beer styles with a 7 BBL brewing system, including ales, lagers, stouts, IPAs, and more. The flexibility of the equipment allows you to experiment with different recipes.

How long does it take to brew a batch of beer on this system?

The brewing time can vary depending on the specific recipe and brewing process, but a typical brew day can range from 5 to 8 hours, followed by fermentation and conditioning, which may take several weeks.

What utilities are required for this brewing equipment setup?

You will need access to water, electricity, and natural gas or propane, depending on your heating method. Adequate drainage, ventilation, and a clean brewing space are also essential for safe and efficient operations.

Is this brewing equipment customizable to my specific needs?

We offer customizable options for brewing equipment, allowing you to tailor the system to your brewery's unique requirements, including vessel configuration, automation level, and material choices.

What is the typical maintenance schedule for this equipment?

Regular maintenance is crucial to ensure the longevity and efficiency of the equipment. Maintenance tasks may include cleaning, sanitizing, inspecting seals and gaskets, and replacing worn or damaged parts as needed.

Can I expand my brewery with this equipment in the future?

The scalability of your brewery depends on various factors, including your available space and budget. Many breweries choose to add additional fermenters, conditioning tanks, and packaging equipment to expand their production capabilities.

Are there any regulatory or licensing requirements for operating this equipment?

Regulatory and licensing requirements for operating a small-scale brewery can vary by location and may include federal, state, and local permits and licenses. It's essential to research and comply with all applicable regulations.

What kind of support and training are provided with the purchase of this equipment?

We offer training and support to help you set up, operate, and maintain your brewing equipment. Inquire about the level of support and training available when making your purchase.