Commercial beer brewery equipment refers to the specialized machinery and facilities used in large-scale beer production for commercial purposes. This equipment is designed to handle the various stages of the brewing process efficiently and at a higher volume than what is typically used in homebrewing.

Commercial beer brewery equipment is the backbone of any large-scale brewing operation. From milling to packaging, each component plays a crucial role in producing high-quality beer. In this article, we'll explore the key specifications and approximate pricing for various types of commercial brewery equipment.

Microbrewery equipment

Microbrewery equipment refers to specialized machinery and facilities used in small-scale beer production for commercial purposes. Unlike large commercial breweries, microbreweries typically produce beer in smaller batches, allowing for more experimentation with flavors and styles.

Medium-Large brewery equipment

Medium-large brewery equipment refers to the specialized machinery and facilities used in breweries that produce beer on a larger scale than microbreweries but are still smaller than the large commercial breweries operated by major beer companies. These breweries have the capacity to produce substantial volumes of beer for distribution on a regional or national level.

Fermentation system

A fermentation system in brewing refers to the set of equipment and processes used to facilitate the fermentation of wort into beer. This critical stage of beer production is where yeast consumes the sugars in the wort, producing alcohol, carbon dioxide, and various flavor compounds.

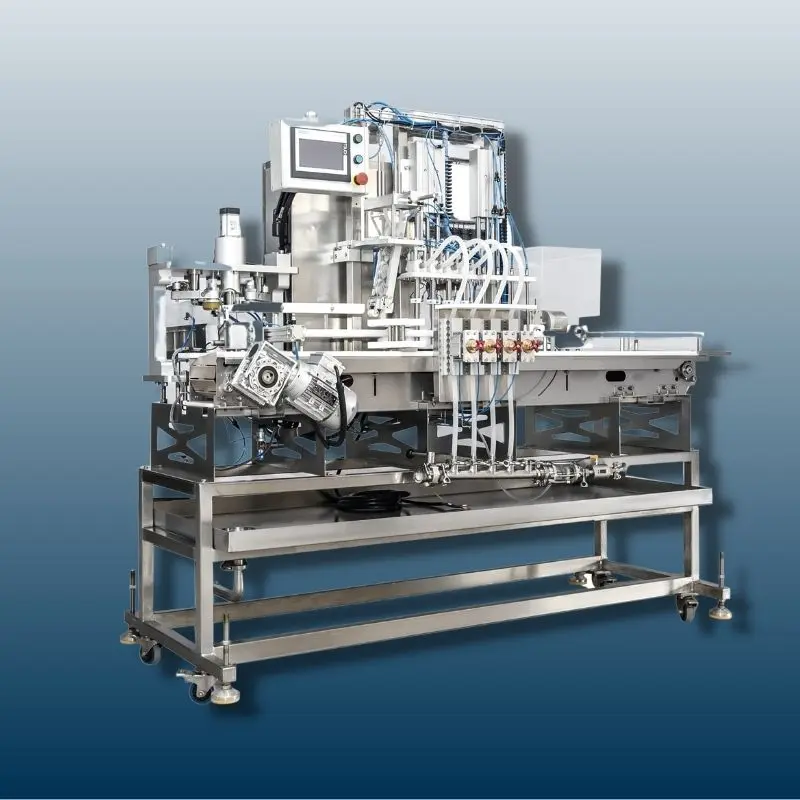

Beer & beverage filling machine

A beer and beverage filling machine is specialized equipment used in breweries and beverage production facilities to fill bottles, cans, or other containers with liquid beverages, including beer, soft drinks, juices, and other non-alcoholic drinks. These machines are designed to efficiently and accurately fill containers with the desired amount of liquid while minimizing spillage and maintaining product quality.

Brewery accessories

Taking Microbrewery equipment as an example, let's analyze the Microbrewery equipment system in detail.

Milling Equipment:

Specification: Milling equipment is designed to crush malted grains, facilitating the mashing process. It typically includes a motorized mill with adjustable settings for different grain sizes.

Price Range: $2,500 - $6,000

Mash Tun:

Specification: The mash tun is a vessel equipped with temperature and time controls for mashing. It allows efficient conversion of starches into fermentable sugars.

Price Range: $15,000 - $50,000

Lauter Tun:

Specification: This vessel separates liquid wort from the grain bed after mashing. It features a false bottom or slotted plates for effective drainage.

Price Range: $20,000 - $60,000

Boiling Kettle:

Specification: The boiling kettle is where wort is boiled and hops are added. It includes temperature and pressure controls for precise brewing.

Price Range: $30,000 - $80,000

Heat Exchanger:

Specification: A heat exchanger rapidly cools boiled wort before fermentation. It ensures preservation of delicate flavors and aromas.

Price Range: $10,000 - $25,000

Fermentation Vessels:

Specification: These tanks accommodate the fermentation process. They vary in size and may have open or closed designs, with temperature and pressure controls.

Price Range: $20,000 - $100,000 (per unit)

Yeast Propagation and Storage Tanks:

Specification: These tanks are used for cultivating and storing yeast cultures, maintaining a healthy and consistent yeast supply.

Price Range: $15,000 - $40,000

Conditioning and Maturation Tanks:

Specification: Tanks for aging and conditioning beer post-fermentation, promoting flavor development and clarity. They come in various sizes.

Price Range: $25,000 - $80,000 (per unit)

Filtering Equipment:

Specification: Various methods like DE filters, plate filters, and centrifuges are used to remove solids and haze before packaging.

Price Range: $15,000 - $50,000

Packaging Equipment:

Specification: Bottling lines, canning lines, and kegging systems for packaging finished beer. Includes labeling and packaging machinery.

Price Range: $50,000 - $200,000

Commercial beer brewery equipment is an investment that significantly impacts the quality and efficiency of beer production. Prices can vary based on factors such as capacity, material, and brand. When selecting equipment, it's important to consider production needs, available space, and budget. Consulting with experienced suppliers and industry professionals is recommended to ensure the chosen equipment meets the specific requirements of the brewery.

When selecting commercial brewery equipment, it's important to consider factors such as production capacity, desired beer styles, available space, budget, and long-term growth plans. Additionally, working with experienced suppliers and consulting with brewery professionals can help ensure that the equipment meets the specific needs of the brewery.

291.webp)