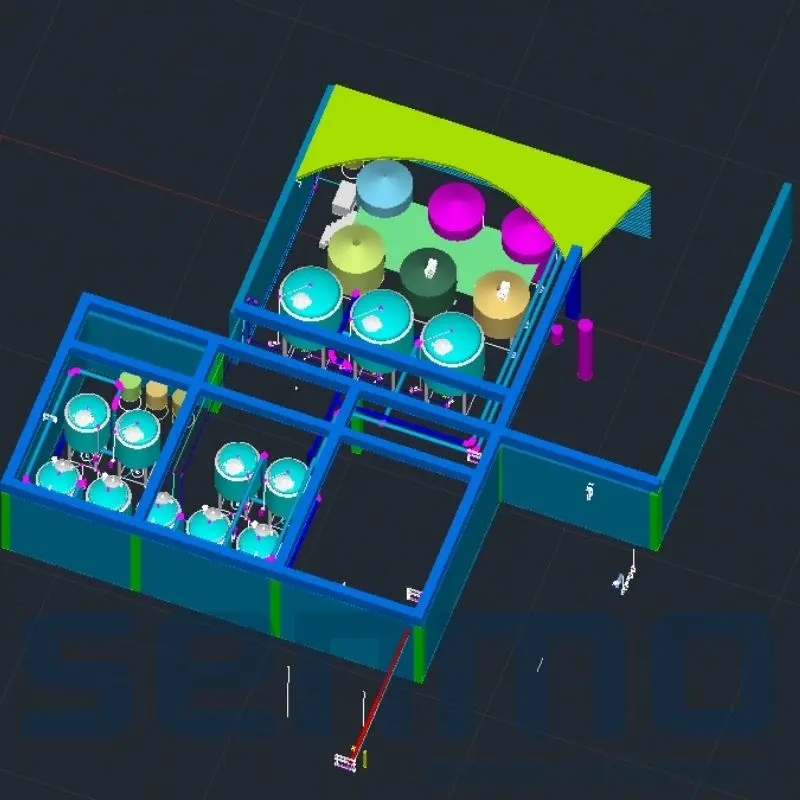

15bbl brewhouse equipment for microbrewery

This is 15bbl brewhouse equipment for microbrewery,the whole set up 15bbl brewhouse equipment is made of SUS304 plate,and the structure is designed as per the microbrewery space layout drawing.Below is the main brewhouse equipment list:

15bbl mash tun of the brewhouse

15bbl lauter tun of the brewhouse

15bbl wort kettle of the brewhouse

15bbl whirlpool tun of the brewhouse

30bbl hot water tank

30bbl cold water tank

15bbl brewhouse equipment pipes and valves

Plate heat exchanger

Operation plateform

15bbl brewhouse control cabinet

15bbl fermentation system

15bbl bright beer tank

Cooling system

CIP cleaning system

The design of the 15bbl brewhouse equipment details is rigorous, so as to maximize the utilization of brewing materials and reduce equipment energy consumption.The 15bbl brewhouse tank plates and accessories are made of international standard SUS304 stainless steel; Our factory use laser cutting and argon shielded welding during the tank production,all vessels' internal do centralized pickling and passivation, accuracy ≤ 0.4 μ m;

Advantages of the 15bbl brewhouse equipment :

1.The 15bbl brewhouse equipment designing strictly follow the craft beer brewing technical process (each brewhouse part has its own transformation from process to purpose)

2. Absorb the research results of latest microbrewery technology and combine the actual situation of craft beer production process. The basic performance is close to the large brewery to ensure the stability of product quality.

3. For microbrewery 15bbl brewhouse equipment operation design,some key parts are designed automatically control,such as temperature control,the glycol water pump control,the steam control. Manual and automatic need combination to ensure the equipment operation reliability.This also will ensure the stability of the beer production.

4. The details of equipment production and processing are fine both inside and outside,without sanitary dead angle.

6.The pipelines connection of the microbrewery 15bbl brewhouse equipment meet the brewing technical process requirements,also combined with the requirements of actual beer production process. (For example, sanitary conditions, oxidation prevention, bottom feeding, top feeding, etc. are all scientific)

7.High performance of the microbrewery 15bbl brewhouse auxiliary machines (for example, the wort pump has variable frequency control,the agitation has frequency control,chiller,steam generator are good brand )

8. The microbrewery 15bbl brewhouse equipment plate material is SUS304 or 316, thickness is 3mm, valve and pipe fitting material is food grade, 100% TIG welding with top quality,do sanding belt on the welding seam...

9. Bigger tank volume. The extra microbrewery 15bbl fermentation tank volume is more than 25%, and boiling kettle is more than 30%,other tanks is 20% extra. Pressure test recorded and inspected irregularly during the process,test pressure 0.4MPa, and maintain the pressure for more than 72 hours without pressure drop. Internal quality of tank body: do acid passivatio,which can reach to 0.4um, and there is no deformation or scratch. The tank liner is smooth and clean,all of the pipe welding seam need to pickled and passivated after polishing.

The microbrewery 15bbl stainless steel fermenters can be individually temperature controlled through glycol jackets and are mostly equipped with accessories such as over-pressure and under pressure valve(PVRV), CIP arm, sanitary sample valve, manway, etc.. The design of fermenters is based on our vast beer knowledge and especially the conical fermenter bottom and the fact that we combine fermentation and maturation in the same vessel is very important. When calculating your fermenting & lagering capacity and configuration, sufficient time fermenting and lagering to produce quality beers must be taken into consideration.

If you are considering to build a microbrewery with a 15bbl brewhouse equipment,it is necessary to have a clear understanding of the requirements for beer brewing technology and equipment technology configuration. If you need the quote of the 15bbl brewhouse equipment for microbrewery, please communicate with professionals and manufacturers in detail. Shandong SENMO Machinery Co., Ltd., as a professional beer equipment production service provider, provides you with professional technical consultation in the early stage, and carries out the microbrewery 15bbl brewhouse equipment design, production, installation, commissioning and other services according to the requirements of beer brewing technology.

FAQ

What is a 15bbl brewhouse, and what does it include?

A 15bbl brewhouse refers to a brewing system with a 15-barrel capacity. It typically includes key components such as a mash tun, lauter tun, kettle, whirlpool, and associated pumps, heat exchangers, and control systems for brewing beer.

Is this brewhouse suitable for a microbrewery?

Yes, a 15bbl brewhouse is often considered suitable for a microbrewery. It allows for larger batch production compared to smaller systems while still maintaining a manageable scale for microbreweries.

What types of beer can I brew with this equipment?

You can brew a wide variety of beer styles with a 15bbl brewhouse, including ales, lagers, stouts, IPAs, and more. The equipment's flexibility allows for creativity in your beer production.

How long does it take to brew a batch of beer on this system?

The brewing time can vary depending on the specific recipe and brewing process, but a typical brew day can range from 6 to 10 hours, followed by fermentation and conditioning, which may take several weeks.

What utilities are required for this brewhouse setup?

You will need access to water, electricity, and natural gas or propane, depending on your heating method. Proper drainage and ventilation are also essential for safe brewing operations.

Is the brewhouse equipment customizable to my specific needs?

We offer customizable options for brewhouse equipment, allowing you to tailor the system to your brewery's specific requirements, such as vessel configuration, automation level, and material choices.

What is the typical maintenance schedule for this equipment?

Regular maintenance is crucial to ensure the longevity and efficiency of the equipment. This may include cleaning, sanitizing, inspecting seals and gaskets, and replacing worn or damaged parts as needed.

Can I expand my brewery with this brewhouse in the future?

The scalability of your brewery depends on various factors, including your available space and budget. Some breweries choose to add additional fermenters, conditioning tanks, and packaging equipment to expand their production capabilities.

Are there any regulatory or licensing requirements for operating this equipment?

The requirements for operating a microbrewery vary by location and may include federal, state, and local permits and licenses. It's essential to research and comply with all applicable regulations.

What kind of support and training are provided with the purchase of this equipment?

We offer training and support to help you set up, operate, and maintain your brewhouse equipment. Inquire about the level of support and training available when making your purchase.